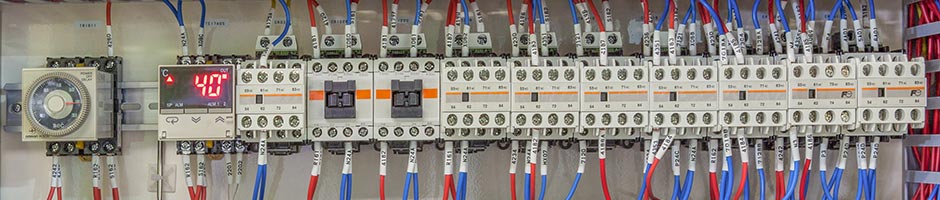

Electrical and mechanical engineering

We have over 20 years of experience within the process and manufacturing industry, managing engineering staff and sub-contractors of all trades. We can plan all engineering activities, work schedules and expenditure to make sure the efficiency of the work force is kept to an optimum.

This can include but is not limited to:

- Developing and maintaining appropriate engineering systems and procedures

- Information is distributed to the appropriate people on a regular basis

- Provide leadership, setting goals and KPI’s, as well as people performance management including appraisals, development and training of staff

- Providing technical support and coaching

- Develop a culture where all staff is committed towards safety

- Drive change management and capital expenditures

- Making sure the reports and budgets are under control, have relevant and accurate data

- Documentation of existing processes and machinery to create an understanding and build the knowledge

- Problem solving and troubleshooting including root cause analysis. We have experience in different levels of analysis such as 5 Why, A3 format, Ishikawa (fishbone diagram), 8D, FMCEA and Kepner Tregoe

- Improve and stabilise processes to get the efficiency needed to increase productivity, quality and reduction of waste

- Process improvements is one of our passions and we thrive on finding creative ways to reduce waste by implementing lean methodology in new designs, existing processes or to increase the productivity

- We have, for many years, implemented different ways to measure and control processes, to get accurate and correct data to minimise the assumption and thereby get a much more accurate optimised outcome

Comments are closed.